Flawil, 23. Juni 2022 – Provisur Technologies simplifies automation for users in the processing of bacon and other irregularly shaped meat and gourmet products. The leading manufacturer of machines for industrial food processing presents a modular, extremely compact complete system. With a small footprint, it ensures even more efficiency in the press-to-slice process – and supports meat processing companies in increasing their yields.

High-performance system, more efficiency and yield

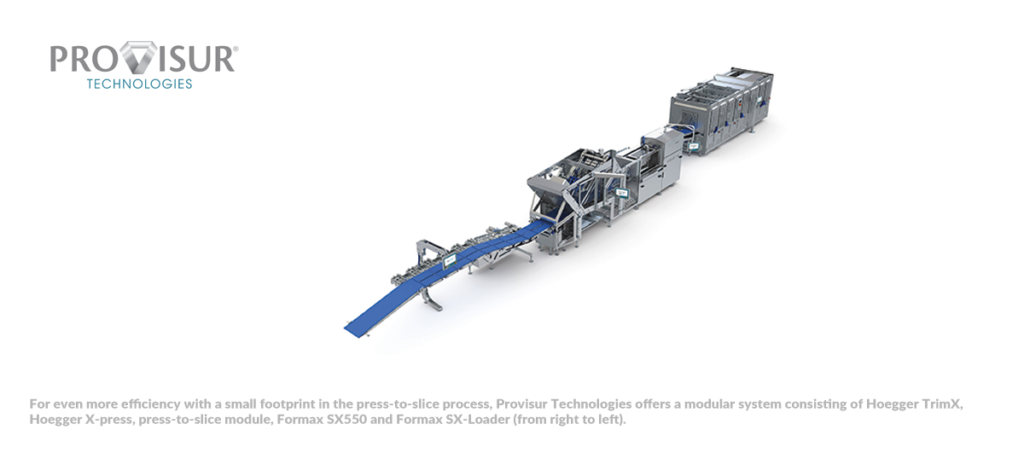

The turnkey line is ideal for products such as streaky bacon, back bacon, smoked ham, fresh meat and much more. It consists of various high-performance modules from Provisur’s product range: the Hoegger X4 form press, the new press-to-slice module with scan and positioning function for two-lane slicing, the new Formax SX550 slicer and the SX-loader. All these modules are perfectly aligned in terms of performance and process sequence to maximize the effectiveness of the entire line. On request, the system can be supplemented with additional modules, like the Hoegger TrimX, which enables fully automatic, intelligent trimming of irregularly shaped products and increases the yield of the slicer by noticeably reducing waste.

New Formax SX550 slicer – heart of the production line

The central element of the press-to-slice system is the new Formax SX550 slicer, which impresses with its high throughput and strong performance. It is suitable for products up to 1600 mm long but is also available in a version for shorter products. The slicer has an extra wide 550 mm slicing chamber, allowing multiple products to be sliced at the same time. The SX550 slicer features a robust, reliable construction as well as a user-friendly design: It is easy to install and set up, can be flexibly configured and, for example, retrofitted with an interleaver. In use, it achieves a particularly high overall cutting performance and reliably processes even demanding products like bacon. The high-performance unit impresses with low operating costs and a minimal footprint, which reduces the space requirement of the complete system.

Perfectly matched components, higher throughput

The synchronization of the modules, thanks to the direct exchange of information, leads to a smooth product flow and thus to an optimized sequence of the process consisting of pressing, scanning and slicing: The meat products are placed in the Hoegger X4 press, which optimally prepares each item for slicing by shaping it perfectly. The press-to-slice module balances the height, creates a 3D scan of each individual product, which is transmitted to the slicer with the simultaneously determined weight to prepare a weight-accurate slicing process. The slicer and press-to-slice module are efficiently controlled from a single control unit. The products are distributed to the two slicing lanes. Here, the Formax SX550 slicer comes into use. It is equipped with two independently driven product guides to achieve the highest portioning accuracy and optimum yield even while cutting two irregularly shaped products simultaneously. The sliced and portioned products are transported to the Formax SX-Loader, which finally ensures uniform, automatic loading of the packaging machine.

„Our complete system for pressing and slicing is a real world first. It combines the entire press-to-slice process on only a small footprint. Thanks to the seamlessly coordinated modules, we achieve excellent portion control with the system, which significantly increases the bottom line efficiency and yield,” explains Gerd Stratenwerth, Sales Manager EAPMEA at Provisur.

About PROVISUR® Technologies:

Provisur® Technologies of Chicago, Illinois, USA, with several branches in Europe, specializes in innovative industrial food processing machines as well as integrated production systems for a wide range of end products. With several well-known and time-honored brands, which are among the technology leaders in the sector, operate under the umbrella of the company. With its product portfolio, divided into the areas of slicing (Cashin®, Formax®, Hoegger®, MultitecTM), further processing (Weiler® and Formax®), DMC (Lutetia®), separation (AM2C®, Beehive®, Hoegger®) and CookChill (Hoegger®), Provisur provides food processing companies with maximum efficiency solutions for requirements of any size. Provisur – many legacies, endless possibilities.

For more information, visit Provisur at www.provisur.com or contact us at info@provisur.com.